The transport sector is responsible for a large proportion of global greenhouse gas emissions. It is essential that it be converted to renewable energy. For cars, the transition to mainly battery-electric vehicles has begun. But for trucks, the technology of choice is not yet clear. Because they are much heavier than cars, they will also need larger batteries. Right now, there is a race between battery electric trucks, hydrogen trucks, and overhead catenary trucks. Yes, you read that right: Trucks with a catenary, like an electric train! How do they work and what are their chances in this competition? Read on to find out more.

Competing Technologies

If you want to power a truck with electric energy, you could just put a big enough battery in it to give it a range comparable to diesel. Right now, batteries are bulky and expensive, but prices are coming down and conventional truck manufacturers have announced new all-electric vehicles for the future.

But even when BEV trucks – or BETs – are widely available, the problems are not solved. Where do you charge them? Standard car charging stations won’t work – it would take forever to charge a BETs battery, even with a 350kW CCS charger. And trucks can’t stop for long. In the highly competitive transportation business, time is money. Ideally, the truck should be able to recharge during the typical 45-minute rest stops that drivers have to make. To do that, you need more power. So a new charging network has to be built where trucks can be charged. A new standard is being developed where batteries can be charged with up to one MW.

Building such a network will be costly and raises the question of how to get all that electrical energy to the truck stops in the first place. We are talking about many megawatts, which means that a lot of new high-capacity lines will have to be laid across the country, along with the necessary substations.

This shows that BETs are more complicated than battery electric cars, so alternatives have a chance.

One alternative is fuel cells. Hydrogen has a high energy density, and you can fill up a truck fairly quickly. For this reason, several truck manufacturers, such as Hyundai, Quantron or Nikola, offer this option (source: Handelsblatt).

The technology is not without its challenges: There are relatively few hydrogen refueling stations, which means that a new infrastructure will have to be built. And then there is the question of where to get all the hydrogen. To make it worthwhile, we need green hydrogen, which is produced from renewable energy. But this form of hydrogen is currently in short supply. And even when more of it becomes available, it may be needed to decarbonize other industries, like steel, that have no other way to meet climate targets.

But there is another option: Why do trucks have to carry all the energy for the entire trip? Why not supply the electrical energy while driving? This was worked out for electric trains more than a hundred years ago: Put up a catenary and let the truck get the power from above!

This is the idea of the catenary truck: Similar to an electric train, there is a catenary above the highway. When the truck reaches the highway, the driver pushes a button and the truck extends a pantograph, which then presses against the catenary. Electricity flows through the pantograph into the truck’s motors and also charges a battery.

Unlike conventional electric locomotives, the truck can also run without a catenary, on regional roads, or when the truck wants to take over from another truck. This is done either with a battery that powers the truck when it is off the grid, or with a conventional internal combustion engine.

There is another difference between electric motors and trucks: The overhead line has two wires in parallel. Each electrical circuit must be closed to allow current to flow from the positive to the negative terminal. For trains, the second terminal is the steel rails that connect the trains to the ground. For trucks with their rubber tires, this is not an option, so the second terminal must also be overhead. This is why the pantrographs look a bit different from the railroad version.

This concept has a number of advantages: The batteries in electric trucks could be smaller because they are only needed for relatively short distances. This could make the trucks lighter and cheaper. And they do not need to stop to recharge. This can be an economic advantage for trucking companies: Drivers do not have to spend time recharging. The infrastructure could also be simpler, because there would be no need to concentrate all the charging capacity at relatively few truck stops, which would require major changes to the power grid. Instead, the power supply to the truck can be spread out over a longer period of time, so that the peak power demand is much lower. This reduces the load on the power grid.

The catenary and pantograph technology is already well developed from the rail sector, so no major technical breakthroughs are needed to make catenary trucks a reality.

Experience

The concept of the catenary truck was proposed by Siemens, a large German technology company. This concept plays well with many of Siemens’ strengths, as they have a long experience with electric trains, motors and power supply.

In recent years, Siemens has partnered with other companies, such as truck maker Scania, to set up real-world trials in California, Sweden, and three different test sites on German highways.

The results of the German projects were evaluated by the Fraunhofer Institute. You can read their project report for free by following this link.

Some of the key takeaways I found in this study were that the concept is technically feasible, but the future prospects depend more on political and organizational issues.

Since catenary trucks have been developed and tested in Germany, which also has a large network of highways, it is natural that Germany would be a leading market for this technology. Other European countries are looking to Germany for leadership in this area. If Germany were to make a serious investment, smaller countries would follow suit and a European network could emerge. So far, however, German ministries have not taken a clear stance on the issue and there has been no commitment to invest in a network.

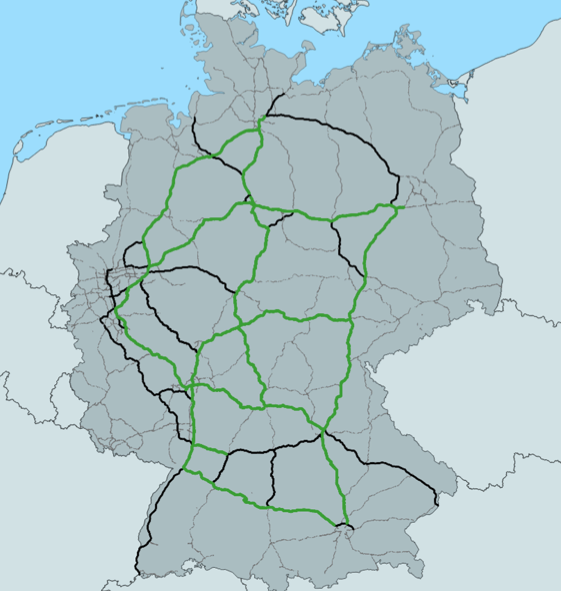

The study calls for the construction of a core network of 4,000 km of the total 13,000 km of highways in Germany. These 4,000 km carry over 65% of long-distance truck traffic. This would be the most efficient use of public money to get a core network up and running. The study estimates the total investment cost for this core network at 10 billion euros.

If Germany were to move forward with this concept, other pressing questions would arise: How would the catenary network be financed and operated? Who would own it? Can it be owned by a for-profit private company, or must it be operated by the state? Can users switch electricity suppliers, and how can they be billed? There are a lot of legal questions to be resolved, and probably new laws to be passed, before construction can begin.

Another important question is who would supply the trucks. Most truck manufacturers do not seem to believe in the technology and are therefore reluctant to invest in it, with the exception of Scania. On the other hand, if a market for catenary trucks were to emerge, it would be relatively easy to develop new trucks, since electric trucks are on every manufacturer’s roadmap anyway. All they would have to do is add a catenary.

Outlook

Catenary trucks work, so they could be an interesting way to reduce greenhouse gas emissions from the transportation sector. But will they really be used on a large scale? That is far from certain at this point. Although the technology works, Germany or another large country would have to commit to the technology and at least fund the construction of the overhead catenary network, along with the regulatory framework needed to operate the fleet of trucks.

It looks like there is currently a window of opportunity for this new technology. However, the longer it remains in the Ilmbo, the more other technologies will be developed. Once there is a large enough network of high-power charging stations, it will no longer be attractive for trucking companies and truck manufacturers to invest in an alternative technology. If the trolley truck is to have a future, that future has to start now or not at all.

2 replies on “Catenary Trucks – The Future of Zero-Emission Road Transport?”

An interesting point of view and worth comment. After 32 years in the automotive industry, including commercial vehicle, the idea of catenary trucks has some merit, but the costs of the infrastructure are not small either. I have driven many times past the test installations close to Frankfurt. Every country has its own challenges, and perhaps in Germany this cold be a possibility, but what happens at the border with, say, Czechia, when the infrastructure is not there yet? The smaller battery now is not big enough, or you have to change tractor which brings its own complications.

Short and perhaps even medium range transport can be accomplished with a BET, long range will require another solution. As you write quite correctly, in my opinion, the MW charger infrastructure required for long range BET, plus the additional need for more BETs (due to load reduction for battery weight) will be a much larger investment with many obstacles. Look at any service area on any EU motorway/autobahn, and you will see dozens if not hundreds of truck bays, yet at night they are also parked on the off and on ramps due to lack of space. Even on minor road parking areas you will find trucks stopped for the night. That is a major infrastructure challenge. You cannot just install a few chargers then expect drivers to wake every hour to rotate the vehicles through them, the majority of those bays need chargers. Close to where I used to live is a service area. There are 100 truck bays either side. At night they were full, and the ramps too, plus the rest area four km away. This service area is one of at least four around Barcelona.

A multi-technology approach will need to be used. BET likely as not for shorter distances, catenary perhaps for some applications, and FCET for longer ranges. Time will tell. One size rarely fits all, even diesel engines came in different sizes.

Hi Stuart,

thank you for your comment! I totally agree with all of your point.

I just want to point out one more fact: Other European countries have expressed their interest to also install catenaries on their highways, but they are waiting for Germany to make the first step. This sounds logical to me, as Germany is not only the largest economoy in Europe, but also the largest transit country, so the standards for trucking are to be set here.

Hope our government will make a move in this direction, as I find this is a rather smart solution. We might need the green hydrogen for many other applications.

BR

Stefan