Maglev trains are a transportation technology that seems to be on the verge of a breakthrough for many decades now. While the Transrapid has failed and the Hyperloop is still in its infancy, the company Max Bögl is working on a completely new version, the Transport System Bögl. We could visit their test tracks in the town of Sengenthal. In this article, we share what we learned about this fascinating new mode of transportation and the opportunities and risks for its widespread adoption.

Introduction

Maglev trains – trains that use magnetic levitation – are a technology that even today sounds like science fiction. When you hear the word, you may think of sleek trains running through futuristic cities. Or you might think of the Hyperloop and its charismatic backer, Elon Musk. Whatever image comes to mind, it is unlikely to be a forest somewhere in Bavaria, Germany. Yet this is where the next step in the development of magnetic levitation trains may be taking place.

Here in the small town of Sengenthal, about 50km from Nuremberg, the company Max Bögl is working on their new transportation system, the “Transport System Bögl”, or TSB for short. Recently, we could visit their test and demonstration site, which is tucked away in the woods and nicely situated on the shore of a beautiful lake.

The Test and Demonstration Site

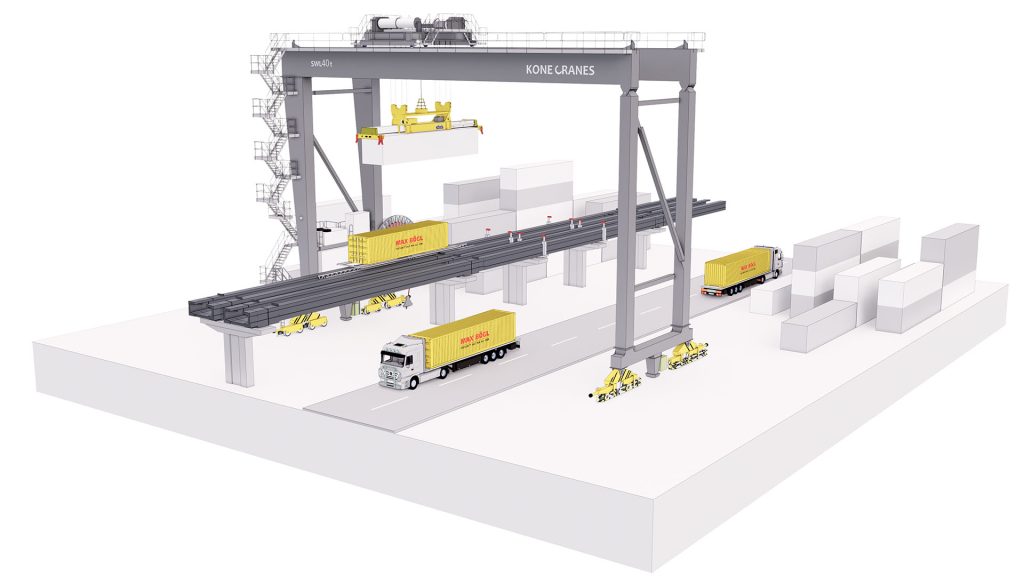

The test and demonstration site in Sengenthal shows the two use cases that Max Bögl has in mind for its new system: Public transport and freight transport, which they call TSB Cargo. More on these two variants in a moment.

The track in Sengenthal is about 900 meters long – not much, but enough to demonstrate the most important aspects of the new system. One is its extreme adaptability to the terrain. Thanks to the maglev drive, the train can climb much steeper slopes than a conventional train – up to 10%! And the test track makes good use of these parameters. Even though the track is so short, the train reaches a maximum speed of 80 km/h on this short track before it has to slow down again. As a passenger, however, you hardly feel this acceleration because there are no screeching wheels and no friction with the track. But you still feel the ups and downs of the track – it almost feels like a roller coaster! So better grab a handle when the ride starts.

After the first ride, we were able to see the train go by – and more importantly, hear it go by. And the thing is: you hardly hear anything! Especially if you compare it to the road that runs parallel to the maglev tracks, you could hardly hear the train.

The very flexible route planning options and low noise emissions make the TSB an ideal choice for urban environments. This brings us to the first use case for TSB: public transport.

TSB for Public Transportation

On its elevated tracks, the TSB looks like a people mover, the kind you might find at a major airport. And indeed, this is one possible use of the TSB. It can move people quickly and efficiently between terminals and other key airport locations. But it can do much more. With a top speed of up to 150 km/h, it can travel much longer distances than a conventional people mover. This makes it a potential alternative to trams, suburban trains and even subways. The high speed and fast acceleration result in a short headway of 80 meters. Assuming the maximum train length proposed by Max Bögl – 6 units – the system can carry 35,000 people per hour per direction.

The high capacity makes the TSB an alternative to conventional mass transit systems.

The TSB runs on elevated tracks, which has some positive aspects for public transport. One is that it requires little grading, which can significantly reduce the time it takes to build a new line. Combined with the smaller radii and steeper gradients, planners have more options for building new lines and making them fit into the landscape, including the urban landscape. Elevated tracks are also cheaper than building new tunnels for subway systems.

The disadvantage of the new tracks is that they are not at all compatible with the existing infrastructure. Whenever the TSB is used to extend an existing line, riders have to change trains. And because the tracks are elevated, cities need elevated stations, which means extensive construction to allow passengers to reach the upper level.

TSB Cargo

The second application for the TSB is the transport of ISO containers. In this variant, each maglev car carries one ISO container, which can be 40 feet containers or even larger. The cars travel separately and autonomously. They can arrive very quickly – a new car may arrive 20 seconds after the previous one has left.

This is much faster than a crane can unload a container ship, so when the crane returns with a fresh container, a new maglev car is waiting to carry it on.

Max Bögl envisions TSB Cargo being used to distribute containers in the hinterland of a container port. The creators do not see it as an alternative to conventional rail, since the cars travel alone and do not form trains. Rather, it is a way to reduce the number of trucks and thus reduce congestion on the busy roads around the port.

In addition to the use case that Max Bögl is promoting, I can also see this system being used in larger factories or in manufacturing clusters where suppliers are located near a larger factory. The magnetic levitation system could move intermediate products from the supplier to the factory in an environmentally friendly way, without congestion – ideal for just-in-time manufacturing. You could think of it as a people mover for goods.

Max Bögl presented the TSB Cargo at the Port of Hamburg during the ITS World Congress 2021. They set up a short track showing the automated loading and unloading of containers. Watch this short video by Max Bögl to learn more:

The video shows scenes shot at the Hamburg demonstration site, mixed with other footage from the Sengenthal demonstration site, and also some computer generated footage.

How it Works

Magnetic Levitation

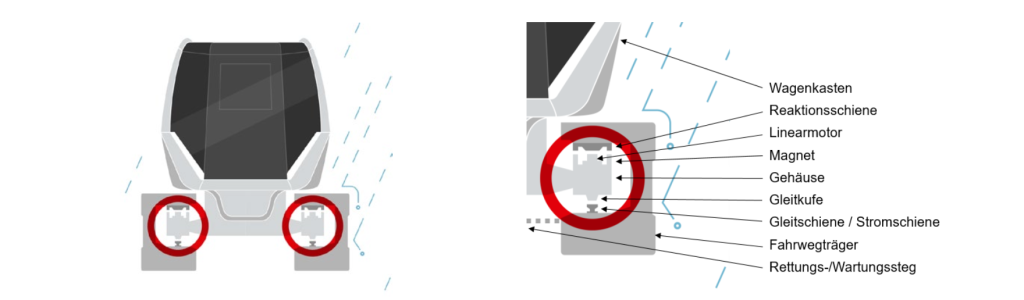

This illustration by Max Bögl shows in a nutshell how the trains move:

As you can see, the track surrounds the lower parts of the train chassis. The train chassis carries the car body. In the cargo variant, the car body is replaced by a flat body with the bolts that carry the ISO container.

An electromagnet in the lower parts of the vehicle creates a magnetic field that pulls the vehicle up. Once the vehicle is suspended in the magnetic field, it is propelled forward by a linear induction motor. This allows the train to move forward without touching the tracks at all (except for the power supply, see below). And because there is almost no friction, the ride is quiet and smooth.

Power Supply

Unlike other maglev trains, the power supply of the trains does not use induction. Instead, it uses a power rail similar to those used in subways. This is a simple, proven, and inexpensive solution. It may not be suitable for high speeds, but it is one aspect where the focus and comparatively low speeds make competitive prices possible.

Train Control and Autonomous Driving

The train control system for the TSB was developed by Max Bögl. It is not related to an existing train control system such as ETCS.

It is designed to enable automatic train operation (ATO), eliminating the need for a driver.

Trains can determine their location at any time through a combination of GPS, odometry and NFC tags along the tracks. Communication with the control center is via radio and also via leaky coaxial cables, which provide a fallback in case of radio interference.

The cars are equipped with a camera at the front, but this is not designed for object recognition – it is more of a fallback. In case of service disruptions, the control center staff can use the cameras to check the condition of the tracks.

Apart from the camera, there are no other sensors to detect the condition of the track, e.g. no radar and no lidar.

Fallback

If the magnetic field that lifts the train fails, the train will fall back to the lower parts of the track. It lands with its skids on the track. This part of the track is covered with a special material that acts as a brake pad. It has just enough friction to stop the train in an emergency – but not enough to stop the train completely. It can still be towed. This means that a broken train can be towed to the nearest maintenance facility. Of course, this will wear down the material on the tracks and on the skids, so the nearest repair shop should not be too far away. The TSB recommends a maximum distance of 80 km.

Evacuation

What happens to passengers in the event of a breakdown? Unlike a conventional train, they cannot simply exit the train through the doors and walk to safety.

But there is a simple solution: passengers can leave the train through the front! Since there is no driver’s cab, the front of the train simply opens up and you can exit the train through the front. You can then walk on the grating that connects the concrete parts of the track. The concrete sides of the tracks also prevent people from falling off, and then they can walk safely back to the nearest station.

This is a simple and ingenious solution. Still, I see potential limitations here, as there are only two doors for an entire train for people to exit. And now imagine that there is a fire at one end of the train, so only one door can be used. All the people from an entire train trying to exit through one door at the same time can become a serious bottleneck. And once off the train, people cannot spread out across the open space – they must move along the tracks to make room for the other passengers.

These difficulties mean that an operator must handle emergency situations very efficiently and guide passengers to safety. This is particularly difficult as there is no staff on the ground to guide people.

This fact will also limit the maximum length of passenger trains, because no matter how long the train gets, there will always be only two doors for evacuation.

Maintenance

Since maglev is a completely new system for many operators, they may worry about how to maintain the trains and the track.

Max Bögl has thought about this, as we could see when we visited the maintenance facilities. Unfortunately we were not able to take pictures, but it was very fascinating.

A maglev train requires less maintenance than a conventional train, because there is no friction to wear down the tracks and wheels, and there are fewer moving parts to grease or clean.

When maintenance is required, special track sections are needed that open at the top. Then the cars can be lifted and maintenance can begin.

Many parts of the cars are conventional off-the-shelf components from the rail industry, such as the electrical converters, cooling systems and connectors. There are relatively few custom parts. As a result, teams accustomed to conventional trains can quickly learn how to maintain a maglev train.

Another advantage is that all parts of the propulsion system are easily accessible once the car is raised. There is no need to cover the parts as they are protected from the environment by the concrete track. This makes maintenance even easier.

By using standard parts that are easily accessible to maintenance personnel, checks and repairs can be carried out very quickly and efficiently.

Tracks

The tracks are made of concrete.

A special feature of the tracks is that they come in segments. The segments can be prefabricated in a factory instead of being constructed on site. Once the track segments are ready, they can be easily shipped in a standard ISO container.

This is one reason for Max Bögl’s claim that a track can be built much faster and cheaper than a standard railway.

Max Bögl demonstrated this concept when they set up their second test and demonstration site in Chengdu, China. They put all the parts for the track in containers and shipped them by rail to Chengdu. Only the train cars were flown in by Antonov aircraft.

Integration into Cities

Elevated railways are not new to large cities. The subways in New York or Berlin, for example, run on elevated tracks. So does the famous suspension Railway in Wuppertal (which I presented in another article). So, in principle, there should be little resistance to another mode of transportation running over people’s heads and in front of their windows. But times have changed – the NIMBY (Not In My Backyard) mentality is widespread in Western societies.

Max Bögl thought about some of these aspects and incorporated them into the design of the track.

The grid in the middle of the track allows light to pass through. This means that the tracks don’t block out all the sunlight, making them more acceptable to pedestrians and people living on the lower floors.

Max Bögl also plans tracks with additional space for planting on the sides. This would add some greenery to the urban landscape, and it might also appease people who are afraid of passengers looking in their windows.

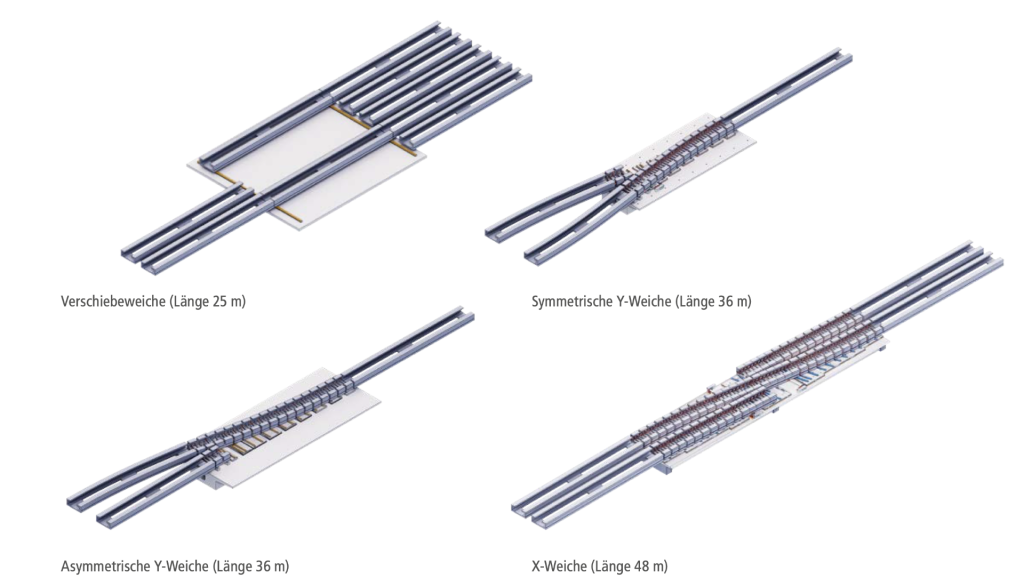

Switches

Monorails like the TSB suffer from the problem of how to build turnouts. Existing solutions for monorails are often quite slow and expensive.

Max Bögl has put a lot of effort into making switches more effective. The TSB switches are articulated at both ends and can therefore move very quickly. They promise that the switch can move from one position to another in less than 15 seconds. This would be fast enough even for TSB Cargo, where the headway of the vehicles is only 20s.

At the test site we could see a Y-switch. Unfortunately, we could not see it in action, it would have been very interesting.

It seems that TSB solves this aspect of monorail switches very well. However, the construction looks very complex and expensive. It is also not clear to me if it can be built on pillars like the rest of the track, or if it has to be built on flat ground.

The TSB concept also includes other types of turnouts like X-turnouts and even a transfer table, but we could not see these in Sengenthal.

In any case, TSB has all the parts it needs to build even more extensive networks. It remains to be seen how much they will cost – if the switches are too expensive, the cost savings from the prefabricated tracks could be wiped out.

Evaluation

I first learned about the Transport System Bögl in the exhibition Futurails in the Nuremberg Transportation Museum (see my article).

This exhibition showed many transportation systems that tried to replace conventional railways in the last 200 years. In this light, the TSB is another contender in a long history of attempts.

Most of these approaches have failed to gain widespread acceptance. Will the TSB be different?

First, we have to acknowledge that the TSB concept gets many things right.

It has high capacity and high speed.

The tracks can be prefabricated and can follow the landscape, making the system fast and cheap to build.

Trains run fast and without noise and CO2 emissions.

Autonomous operation and easy maintenance keep operating costs low.

And the whole system is not only a prototype, it already has the approval of the German railway authority EBA.

Still, there is no real-life, full-scale application of the TSB. Why might that be? Let’s explore some facts that could hinder the further success of even a well thought out mode of transportation.

Who is the First Mover?

It is a chicken and egg problem: no one wants to be the first to try a new technology at scale. Potential customers ask for a reference installation. Until there is one, it is harder to sell the system.

In such a situation, government support is always helpful.

The German Transport Ministry comissioned a feasibility study (you can find it here). The study compares the TSB with conventional trams, metros and suburban trains. It finds in favor of the TSB in many aspects, but also points out some weaknesses, like the ones I mentioned in this article.

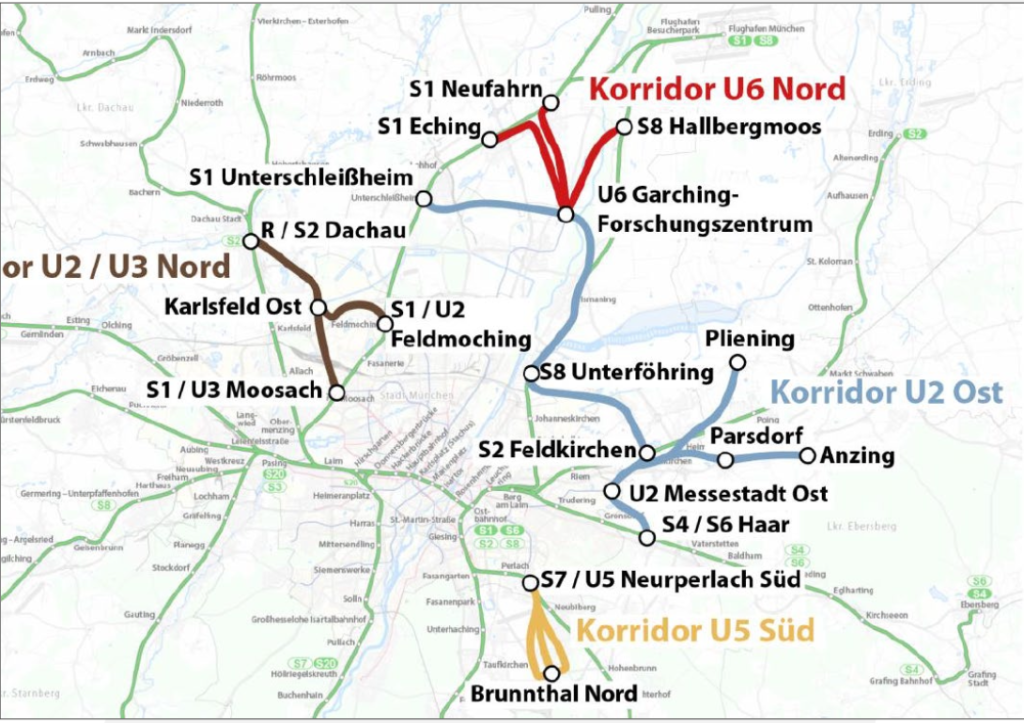

The study was published three years ago, but the TSB is still not under construction. To speed things up, the Bavarian government is funding a feasibility study for a new line in Nuremberg (see press release). This line could replace a planned tram line in the south of Nuremberg. The city of Nuremberg has emphasized that the total cost of the TSB must not be higher than that of the originally planned tramway. If the feasibility study comes to that conclusion, this could become the first commercial TSB line in the world.

Who is the Second Supplier?

Infrastructure operators are always reluctant to invest in something completely new and unproven, as they will have to live with their decision for many years to come. And here I see another reason why demand has been slow so far: there is only one supplier of the system and the components: Max Bögl. Operators ask themselves: What if the company goes bankrupt in a few years? What if they discontinue the product or raise the prices? Max Bögl promotes the “single source” as an advantage of the system, but in my opinion it will reduce the enthusiasm of decision makers to invest in this technology.

How to Connect?

An elevated monorail is incompatible with the existing rail infrastructure. And since many cities already have a lot of rail infrastructure, the question is how to connect the old and new worlds. For passengers, this means changing trains. Decision-makers will have to decide whether the benefits of the new system are worth the inconvenience to their customers. This means that TSB’s best bet in public transport is to build tangential lines in existing networks – lines that are needed but could not be built because of the high cost of building another subway in the outskirts of cities. This is exactly what is happening right now, as the city of Munich investigates the potential use of TSB for tangential connections:

Who is the Competition?

There are many alternatives for decision makers to consider. Although TSB has many advantages over existing rail systems, it has had a difficult time penetrating this market. Operators are familiar with existing systems, and there is a vibrant market for infrastructure, rolling stock, and train control systems, so the failure of one supplier will not jeopardize the operation of a public transit system.

Also, suppliers of existing technology might try to undercut Max Bögl in tenders for new lines just to keep a competing technology out of the market.

If we look at TSB Cargo, the main competition is trucks. With conventional trucks, we could have the same kind of service that TSB Cargo could offer. Right now, every truck needs a driver, and it produces more emissions than a magnetic levitation train. But electric trucks – both battery electric and hydrogen powered – are already on the horizon, eliminating this potential advantage of TSB. And autonomous operation of trucks may one day become a reality – at least in confined areas such as container terminals, it already is.

So the question for a terminal operator will be: Why should I invest in new infrastructure now when I can get the same benefits in a few years with electric, autonomous trucks? This is a question Max Bögl will need a good answer to.

What About Other Maglevs?

We also have to keep in mind that the TSB is not the first maglev line on the market. Although it is not well known in Germany, there are some maglev lines for public transport in Asia, especially in Japan and South Korea (see this Wikipedia article). They have been around for a few decades now, but they have not seen widespread use in Asia either. The maglev at Incheon Airport (see Wikipedia) is even closed since 2022, partly due to low ridership and partly due to high maintenance costs, as spare parts for the rare trains are more expensive than for conventional trains and monorails.

How Much Will It Really Cost?

As always, one of the most important questions for any investor is: How much will it cost me? I do not have any hard numbers yet. The construction of the tracks might be cheaper compared to conventional rail, since no grading is required and the parts can be prefabricated. On the other hand, the turnouts are very complex and could be very expensive. Also, the cars are likely to be quite expensive, as each car will need to be equipped with a drivetrain, compared to conventional trains where only one locomotive or articulated car needs an engine. Another factor driving up prices is that there is no mass production yet, so there are no economies of scale.

And because the system is completely new, each new line requires new maintenance facilities. For conventional trains, cities often have them, so adding a line does not mean building a new repair shop.

All in all, I see the potential for the TSB to be cheaper for the operator, but without hard numbers it is hard to say.

Outlook

The points I have listed above could be major obstacles to real life implementation of the TSB. I think the TSB has a lot going for it, but it needs to break through the last barrier to convince decision makers to invest in a future-proof technology. And to make that breakthrough, Max Bögl needs to build more trust. Trust that the connection to the existing transportation system will work seamlessly. Trust that the operating costs are really lower than for a conventional suburban train or tram. And trust that the operator will be able to find spare parts even if Max Bögl is no longer available as a supplier.

Some of these concerns can only be addressed when we have the first real applications. Perhaps government support will help, or perhaps Max Bögl could finance its own cargo system together with an investor.

But confidence in the long-term availability of the technology can only be built if Max Bögl finds some partners and opens up to second-source suppliers. Only with a functioning market will customers have confidence in the long-term prospects of a new and expensive technology.

I sincerely hope that the team at Max Bögl can build this trust, because they already have the technology and the team spirit to bring this new transportation system to life.

Notes

We would like to thank Max Bögl for the opportunity to visit their test and demonstration site in Sengenthal.

Special thanks to Mr. Stefan Geiger who showed us around and answered all our questions.

Our trip to Sengenthal was not sponsored by TSB.

All photos and videos in this article: Copyright Mariya & Stefan Heinbockel unless otherwise noted.

One reply on “Transport System Bögl – The Future of Maglev Trains?”

[…] a linear motor. It is used in some types of machines. It also propels Maglev trains, like the Transport System Bögl about which I wrote an article back in April.To learn how a linear motor works, check […]